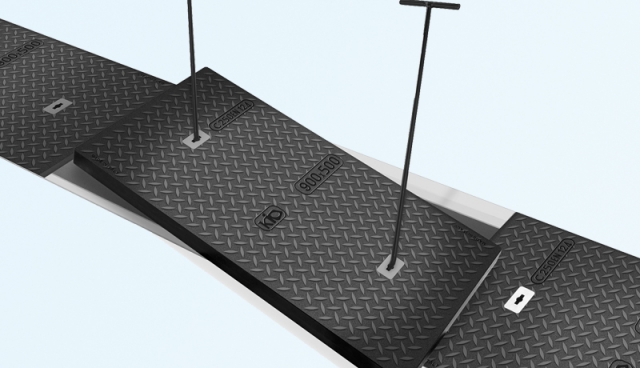

Fibre-Reinforced Polymer (FRP) (also called fibre-reinforced plastic) is a composite material made of a polymer matrix reinforced with fibres. The fibres are usually glass (GFRP), carbon (CFRP), aramid (ARFP), or basalt (BFRP). FRP is one of the highest strength-to-weight ratios of any material, it is strong and durable, ready for years of dependable use. Unlike steel, FRP has memory, springing back to its original shape when deflected. Even major impacts inflict little damage without failure. FRP can also be custom designed and fabricated to provide the distinct reinforcing functions to meet the specific strength and corrosion and abrasion resistance requirements. FRP has been widely used in the automotive, marine, mining, oil, gas, wastewater treatment facilities, power plant, and construction industries.

Characteristics of Fibre-Reinforced Polymer (FRP)

- Light weight with high strength

- Corrosion resistance

- Impact resistance

- Dimensional stability

- Electrically non-conductive

- Non-magnetic

- Non-sparking

- Low thermal conductivity

- Rapid installation with standard tools

- RF transparency

- UV Protection

Compare with steel, timber or other construction materials, FRP is the most economical and efficient solution for harsh industrial and demanding structural construction. FRP also able to withstand severe weather conditions of Australia. Grating FRP Australia’s is a premier FRP products supplier and designer of high-quality Fibreglass Reinforced Polymer (FRP) structural products and systems, providing one of the industry’s broadest product and service offerings. From the design and supply of moulded and pultruded fibreglass gratings and structural shapes to complete structural design and fabrication, and to manage FRP projects at various stages to meet the project specifications and requirements. Grating FRP Australia has been working with clients from various industries and we provide the in-depth technical advice and innovative FRP solutions to our clients.